Soldering Guidance

Suggested Specification and Guidance using Lead-Free Soldering for Potentiometers

For Manual Soldering:-

- In tests, ‘hand-soldering’ with a tip (Temperature 370°C/700°F maximum, Spade 1.2mm) applied for a maximum of 5 seconds using SnAgCu ‘lead free’ solder has been found to provide an adequate joint when applied to our potentiometer terminals.

- Terminals must not be overheated

We recommend the use of Ordinary Wiring (OW) terminals when hand soldering.

For Automated or Semi-Automated Soldering Equipment:-

- Flux of 0.82 specific gravity applied by foam fluxer, shall be used. Foam head shall be limited to the height which is half thickness of printed circuit board to be soldered. No flux should be allowed to run up onto resistive element board of potentiometer and the surface of printed circuit board.

- Regarding preheating the entire flow duration should not exceed 2 minutes and soldering surface temperature (under-surface of PCB) shall be settled within 100°C.

- Solder Dipping is to be performed within 4 seconds at 260°C or below.

Regardless of soldering equipment and method, soldering must not be carried out more than once.

REMARKS:- This specification is not recommended for, nor applicable to, reflow soldering.

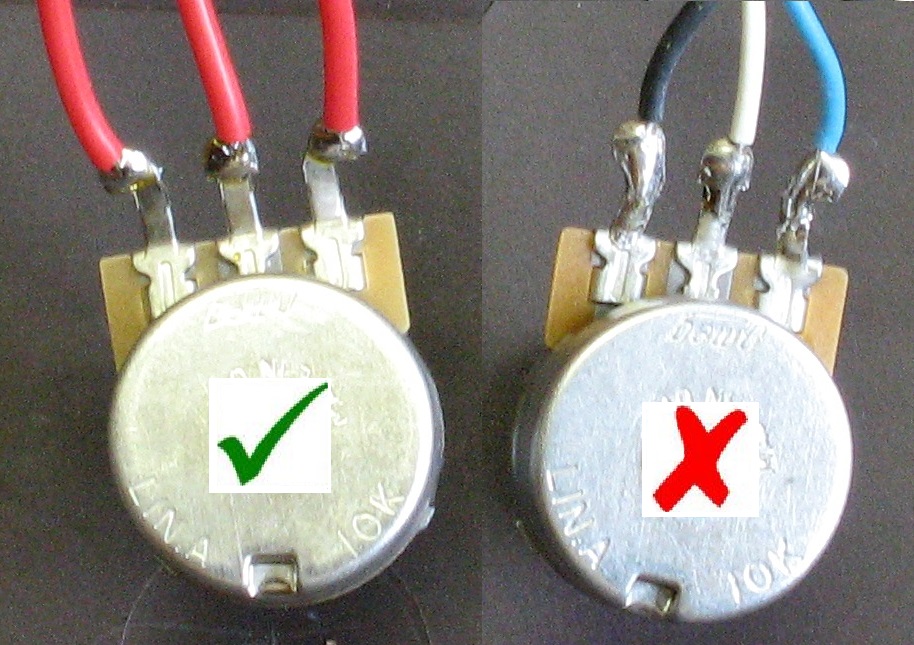

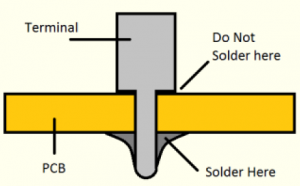

CAUTION:- Please avoid solder and flux creeping towards the board, also avoid soldering on upper surface of PCB as shown here.

The information above is supplied in good faith but the customer is politely reminded that it is their responsibility to check the suitability of our products for their particular application, production techniques and processes.